One of the most misunderstood and misused components of conductive steam tracing systems is heat transfer compound, or HTC. HTC is a viscous mastic designed to fill small air gaps between the tracing element and the object to be heated. Heat transfer compound is considerably more effective at transferring heat than static air, but has relatively poor thermal conductivity compared to the other components in a steam tracing system. If used in very thin layers, however, HTC helps maximize the performance of heating systems. This paper discusses and demonstrates why the performance and success of conductive steam tracing systems is highly dependent upon proper installation and use of HTC.

Around the world, sulfur operations rely heavily on high performance steam tracing and jacketing to heat piping, equipment, and vessels. Failure to properly heat these systems can cause sulfur to freeze and ultimately shut down a processing plant or even an entire refinery. To ensure that a steam tracing system will operate as designed, especially for critical processes like liquid sulfur and vapors with sulfur compounds, proper system installation is critical for long-term success.

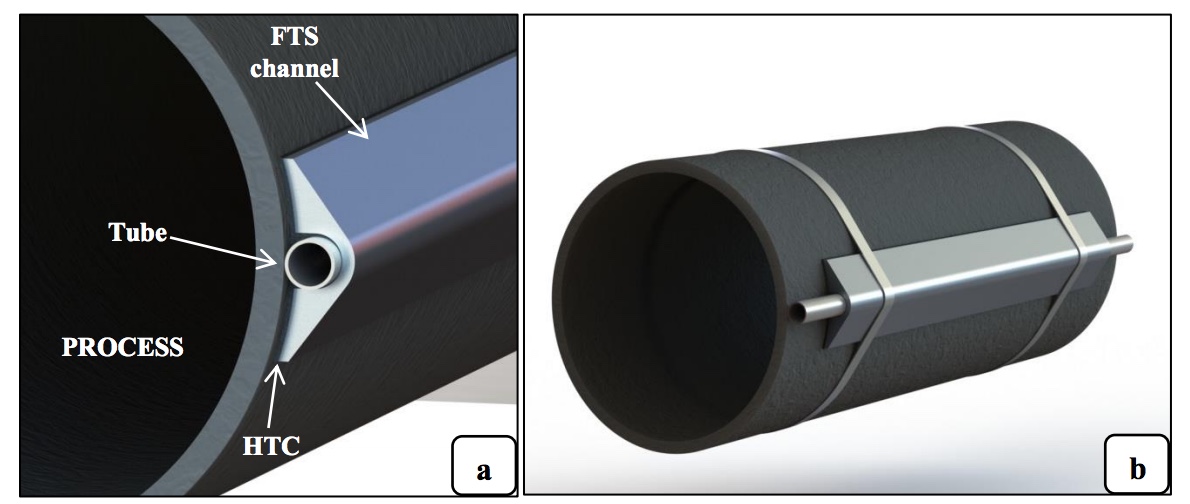

To help understand how HTC thickness and installation quality affect tracing performance in critical operations like those involving sulfur, QMax Industries Inc. focused on testing two high performance steam tracing technologies: FTS (Fluid Tracing System) and CST (Carbon Steel Tracing). The systems were tested extensively with controlled HTC thicknesses for their effectiveness in melting elemental sulfur by tracing a sulfur-filled vessel in a QMax Industries Inc. facility. The outcome of improperly installing HTC, regardless of the reason or steam tracing technology used was consistent: as the HTC layer thickness between the tracing and pipe or vessel increases, the overall heat transfer rate from steam to process decreases. Increasing HTC thickness by only 1/16-inch from an optimal thickness of 1/32-inch increased the time required to melt elemental sulfur by as much as 70%.

Click to download the complete whitepaper on “Understanding Installation of Steam Tracing for Long-Term Application Success”. If you have questions about using steam tracing in your facility, contact the team at Campbell-Sevey.

One of the most misunderstood and misused components of conductive steam tracing systems is heat transfer compound, or HTC. HTC is a viscous mastic designed to fill small air gaps between the tracing element and the object to be heated. Heat transfer compound is considerably more effective at transferring heat than static air, but has relatively poor thermal conductivity compared to the other components in a steam tracing system. If used in very thin layers, however, HTC helps maximize the performance of heating systems. This paper discusses and demonstrates why the performance and success of conductive steam tracing systems is highly dependent upon proper installation and use of HTC.

Around the world, sulfur operations rely heavily on high performance steam tracing and jacketing to heat piping, equipment, and vessels. Failure to properly heat these systems can cause sulfur to freeze and ultimately shut down a processing plant or even an entire refinery. To ensure that a steam tracing system will operate as designed, especially for critical processes like liquid sulfur and vapors with sulfur compounds, proper system installation is critical for long-term success.

To help understand how HTC thickness and installation quality affect tracing performance in critical operations like those involving sulfur, QMax Industries Inc. focused on testing two high performance steam tracing technologies: FTS (Fluid Tracing System) and CST (Carbon Steel Tracing). The systems were tested extensively with controlled HTC thicknesses for their effectiveness in melting elemental sulfur by tracing a sulfur-filled vessel in a QMax Industries Inc. facility. The outcome of improperly installing HTC, regardless of the reason or steam tracing technology used was consistent: as the HTC layer thickness between the tracing and pipe or vessel increases, the overall heat transfer rate from steam to process decreases. Increasing HTC thickness by only 1/16-inch from an optimal thickness of 1/32-inch increased the time required to melt elemental sulfur by as much as 70%.

Click to download the complete whitepaper on “Understanding Installation of Steam Tracing for Long-Term Application Success”. If you have questions about using steam tracing in your facility, contact the team at Campbell-Sevey.Understanding Installation of Steam Tracing for Long-Term Application Success