Steam Trap Surveys

Every mechanical system requires maintenance. Just like your car would break down without regular oil changes and tune-ups, the components in a steam system cannot be expected to work perfectly forever. Moving parts wear, soft good deteriorate, and failures happen. A steam trap survey is an excellent way to get ahead of small maintenance problems […]

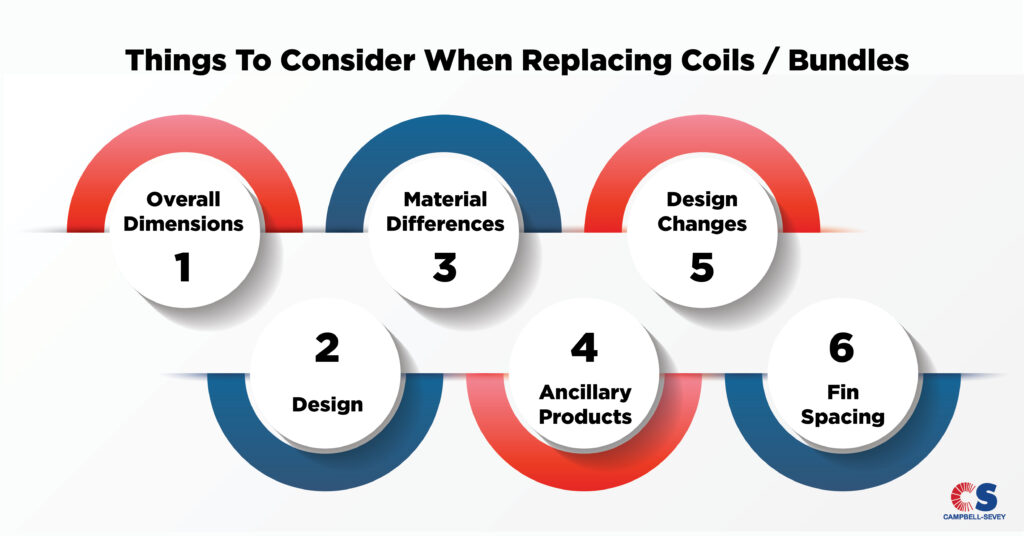

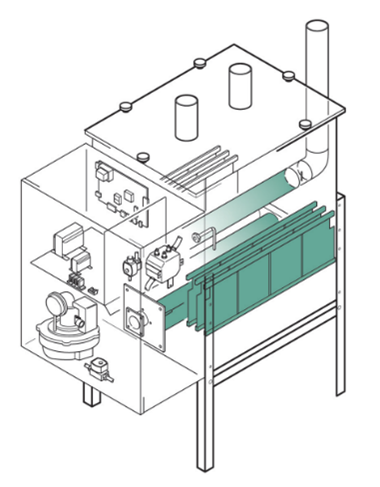

THE HIGH COST OF SIMPLE MISTAKES – MEASURING COILS & HEAT EXCHANGERS

We have all learned the old adage: “Measure twice, cut once.” It is always worthwhile to double-check your information before diving into a project. This applies to everything from building a birdhouse to building a skyscraper. In our industry, it certainly applies to coils and tube bundles. Coils are used to heat up or cool […]

Brain Surgery – How Hard Can It Be?

When Armstrong introduced the “Brain” family of digital mixing valves, they introduced some much-needed improvements to domestic hot water systems around the world. Hospitals, universities, nursing homes, and many other institutions have seen the benefits of using these valves, as they help with legionella prevention, scald safety, reliability, and building automation. The “Brain” mixing valves […]

Let’s Talk About Humidifiers

Let’s Talk About Humidifiers The concept of humidification is relatively simple. It’s the act of adding water vapor into dry air. A key measurement of humidity is called relative humidity, or RH. This is the amount of vapor in the air compared to the amount the air can hold at a given temperature. Warm air […]

Campbell-Sevey to attend the 2024 ABMA Boiler Technology Conference and Expo

Campbell-Sevey to attend the 2024 ABMA Boiler Technology Conference and Expo Campbell-Sevey is thrilled to announce that we will be participating in the upcoming American Boiler Manufacturers Association (ABMA) Boiler Technology Conference and Expo, scheduled to take place in Denver, CO, from May 1-3, 2024. As a leading player in the boiler industry, we understand […]

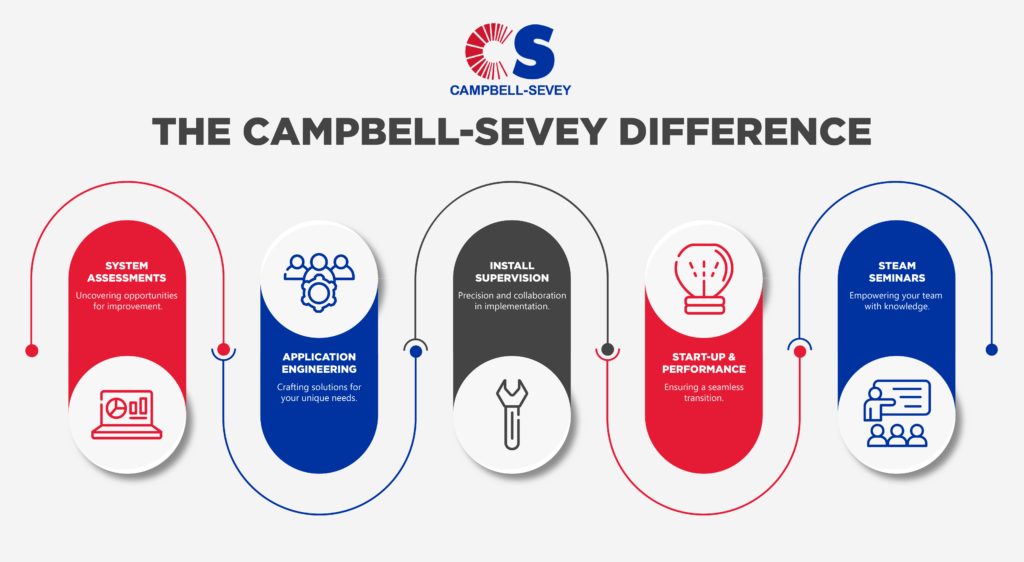

Unveiling the Campbell-Sevey Difference: Elevating Steam System Efficiency

In the intricate world of industrial processes, the efficiency of steam systems is paramount. At Campbell-Sevey, we go beyond providing mere solutions – we deliver a comprehensive suite of services designed to address the unique challenges faced by our customers. Join us as we explore how our key offerings – application engineering, start-up, and performance, […]

2024 Steam Energy Conservation Seminars

2024 Steam Energy Conservation Seminars In the ever-evolving landscape of energy conservation, staying ahead of the curve is crucial for businesses seeking efficiency, cost savings, and sustainability. Campbell-Sevey’s 2024 Steam Energy Conservation Seminars promise to be a game-changer, offering participants the unique opportunity to bridge the gap between textbook knowledge and practical field applications. Exploring […]

Steam System Dangers with Uncontrolled Gases

The Dangers of Uncontrolled Gases In Your Steam System One of the most serious and costly hazards that can befall your steam system is the buildup of air and noncondensible gases (usually carbon dioxide and oxygen). Left unattended, such accumulations accelerate corrosion and block flow, resulting in leaks, steam or water hammer, reduced heat transfer […]

Steam System Troubleshooting – 4 Tips You Should Know

4 Installation Tips For Troubleshooting Steam Systems We recommend you do not repair or replace suspect pressure reducing valves or steam traps without first considering four potential steam system installation pitfalls. When a pressure reducing valve (PRV) or steam trap appears to be malfunctioning, there is a strong tendency to simply replace the suspect part […]

Verify the Correct PRV Size – Steam System Troubleshooting Tip #2

TIP #2: Verify the Correct PRV Size to not cause valve wear and erratic pressure control. Installation of an oversized PRV will often cause increased valve wear and erratic pressure control. The selection of the proper PRV should be based on the supply pressure, delivery pressure, and amount of steam required to be delivered to […]