Steam turbines are well suited as prime movers for driving boiler feedwater pumps, forced or induced-draft fans, blowers, air compressors, and other rotating equipment. This service generally calls for a backpressure noncondensing steam turbine. The low-pressure steam turbine exhaust is available for feedwater heating, preheating of deaerator makeup water, and/or process requirements.

Steam turbine drives are equipped with throttling valves or nozzle governors to modulate steam flow and achieve variable speed operation. The steam turbine drive is thus capable of serving the same function as an induction motor coupled to an inverter or adjustable speed drive. Steam turbine drives can operate over a broad speed range and do not fail when overloaded. They also exhibit the high starting torque required for constant torque loads such as positive displacement pumps.

Steam turbines are inherently rugged and reliable low-maintenance devices. They are easy to control and offer enclosed, nonsparking operation suitable for use in explosive atmospheres or highly corrosive environments. Steam turbines provide fast, reliable starting capability and are particularly adaptable for direct connection to equipment that rotates at high speeds. Steam turbine drives may be installed for continuous duty under severe operating conditions, or used for load shaping (e.g., demand limiting), standby, or emergency service.

Steam turbine performance is expressed in terms of isentropic efficiency or steam rate (the steam requirement of the turbine per unit of shaft power produced). Steam rates are given in terms of pounds per horsepower-hour (lb/hp-hr) or pounds per kilowatt-hour (lb/kWh).

Example

A 300-hp steam turbine has an isentropic efficiency of 43% and a steam rate of 26 lb/hp-hr given the introduction of 600-pounds-per-square-inch-gauge (psig)/750°F steam with a 40-psig/486°F exhaust. What steam flow is necessary to replace a fully-loaded 300-hp feedwater pump drive motor?

Steam Flow = 26 lb/hp-hr x 300 hp = 7,800 lb/hr

An examination of the ASME steam tables reveals that this steam turbine would utilize 103 Btu/lb of steam or 0.80 million Btu (MMBtu) of thermal energy per hour. Given a natural gas cost of $8.00/MMBtu and a boiler efficiency of 80%, the fuel-related cost of steam turbine operation is (0.80 MMBtu/hr/0.80 x $8.00/ MMBtu) = $8.00/hr.

In comparison, a 300-hp motor with a full-load efficiency of 95% would require:

300 hp x (0.746 kW/hp) x 100/95 = 235.6 kWh/hr

In this example, the steam turbine drive would provide energy cost savings when the price of electricity exceeds:

$8.00/hr

––––––––––––––––

235.6 kWh/hr x $/100 cents

= 3.4 cents/kWh ($0.034/kWh)

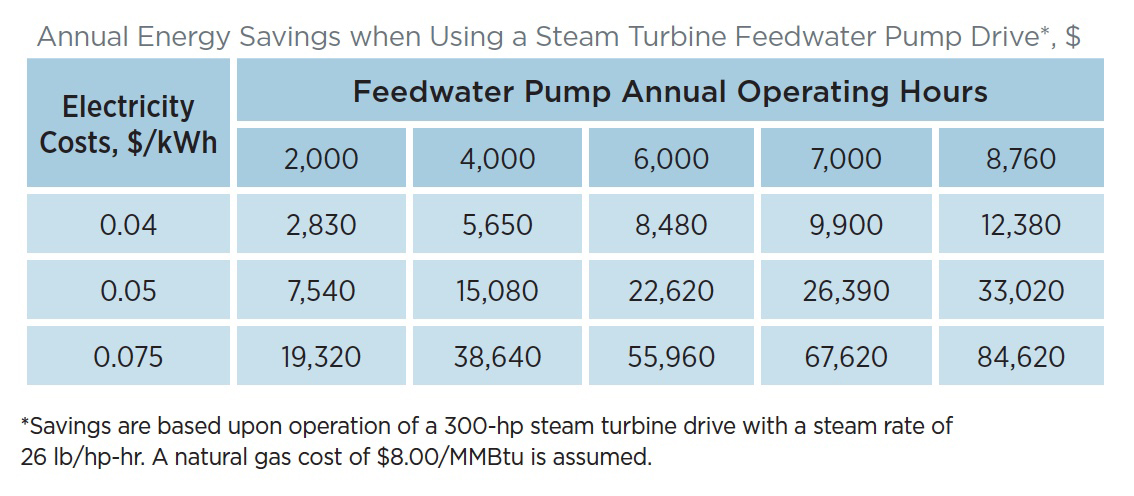

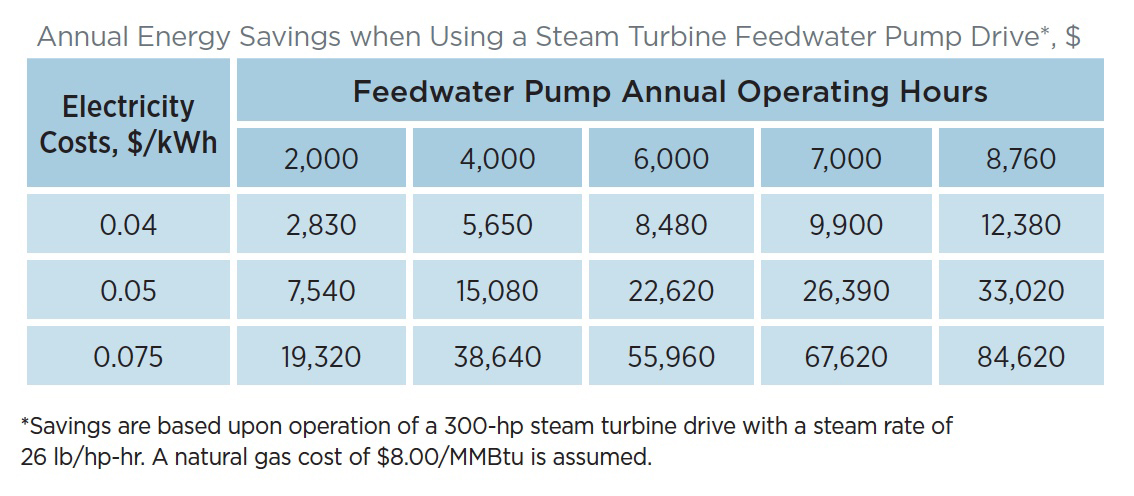

The total annual energy savings are strongly dependent upon the facility energy cost and the hours per year of feedwater pump operation. Annual energy savings are given in the table below for various electrical rates and pump operating schedules. In addition to operating cost savings, steam turbine maintenance costs should be compared with electric motor maintenance expenses

Steam Turbine Flexibility

Steam Turbine Flexibility

Equipment redundancy and improved reliability can be obtained by mounting a steam turbine drive and an electric motor on opposite ends of the driven-equipment shaft. You can then select either the motor or turbine as the prime mover by increasing or decreasing the turbine speed relative to the synchronous speed of the motor.

This tip is provided by the U.S. Department of Energy – Energy Efficiency and Renewable Energy and originally adapted from material provided by the TurboSteam Corporation and reviewed by the AMO Steam Technical Subcommittee.

For suggested actions and resources, click to download the complete US Department of Energy Tip Sheet.

Steam Turbine Flexibility

Equipment redundancy and improved reliability can be obtained by mounting a steam turbine drive and an electric motor on opposite ends of the driven-equipment shaft. You can then select either the motor or turbine as the prime mover by increasing or decreasing the turbine speed relative to the synchronous speed of the motor.

This tip is provided by the U.S. Department of Energy – Energy Efficiency and Renewable Energy and originally adapted from material provided by the TurboSteam Corporation and reviewed by the AMO Steam Technical Subcommittee. For suggested actions and resources, click to download the complete US Department of Energy Tip Sheet.

Steam Turbine Flexibility

Equipment redundancy and improved reliability can be obtained by mounting a steam turbine drive and an electric motor on opposite ends of the driven-equipment shaft. You can then select either the motor or turbine as the prime mover by increasing or decreasing the turbine speed relative to the synchronous speed of the motor.

This tip is provided by the U.S. Department of Energy – Energy Efficiency and Renewable Energy and originally adapted from material provided by the TurboSteam Corporation and reviewed by the AMO Steam Technical Subcommittee. For suggested actions and resources, click to download the complete US Department of Energy Tip Sheet.