In steam systems that have not been maintained for 3 to 5 years, between 15% to 30% of the installed steam traps may have failed—thus allowing live steam to escape into the condensate return system. In systems with a regularly scheduled maintenance program, leaking traps should account for less than 5% of the trap population.

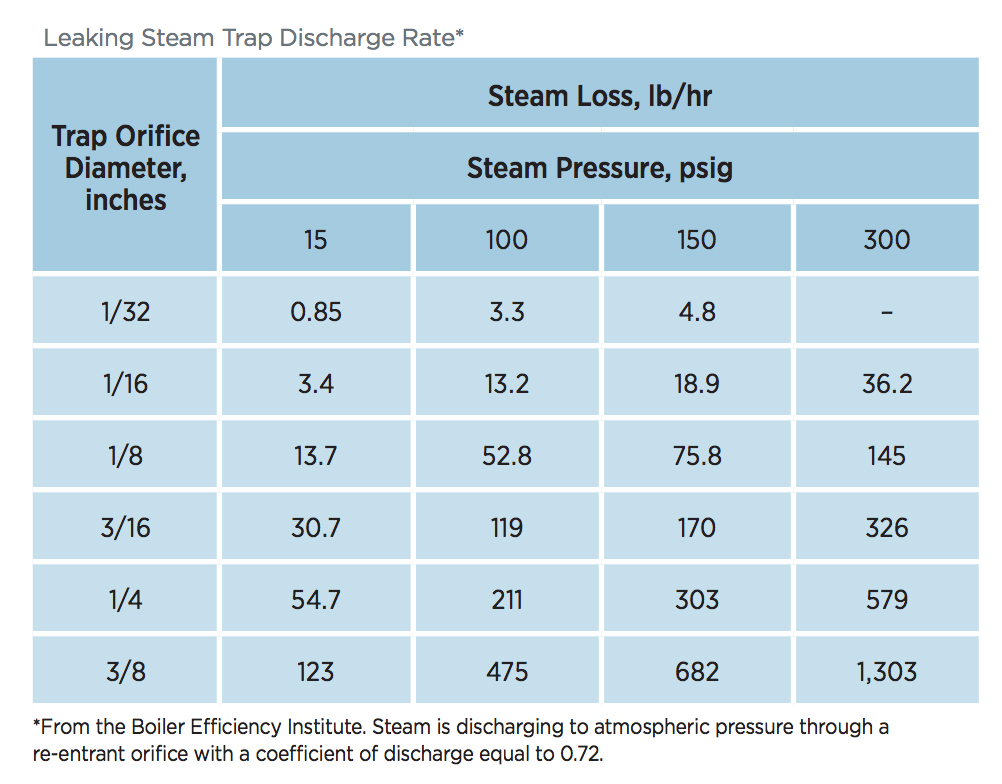

If your steam distribution system includes more than 500 traps, a steam trap survey will probably reveal significant steam losses. Example: In a plant where the value of steam is $10.00 per thousand pounds ($10.00/1,000 lb), an inspection program indicates that a trap on a 150-pound-per-square-inchgauge (psig) steam line is stuck open. The trap orifice is 1/8th inch in diameter.

The table shows the estimated steam loss as 75.8 pounds per hour (lb/hr). After the failed trap is repaired, annual savings are: Annual Savings = 75.8 lb/hr x 8,760 hr/yr x $10.00/1,000 lb = $6,640

Download this “Inspect and Repair Steam Traps” tip sheet from the Department of Energy for more information.

This tip is provided by the U.S. Department of Energy – Energy Efficiency and Renewable Energy and originally published by the Industrial Energy Extension Service of Georgia Tech.