E-Tech’s ThermoCharger Systems maximize boiler efficiency of existing systems by 2% or more … with minimal investment!

Now there is a cost-effective solution to help operators achieve a minimum 2% of additional efficiency from existing systems that use a minimum of 20% makeup water or have a large hot process water load – E-Tech’s ThermoCharger.

The operating principle behind the ThermoCharger is simple:

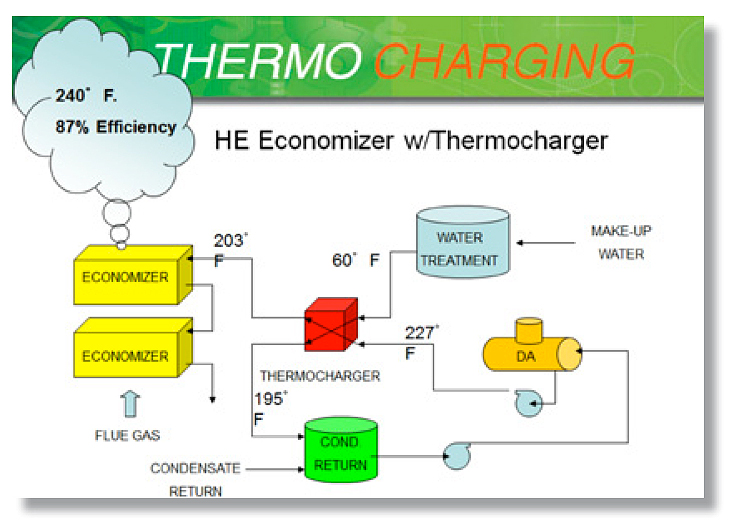

The unit exchanges heat between two water systems, then channels each to the part of the system where it will enhance efficiency. The illustration above shows how its two functions operate:

- Water sources include make-up water and hot process water for one or more areas of the plant.

- The ThermoCharger uses cold water (about 60ºF) to cool deaerated water (typically about 227ºF) before sending it to an economizer for further heat recovery.

- The ThermoCharger lowers the deaerated water temperature by 24ºF, thus reducing the amount of heat energy that is lost up the flue due to an overtaxed economizer.

- In its second function, the unit sends the makeup water (now at about 195ºF) to the processwater holding tank. Here it is now preheated water, lowering the energy demand during the deaeration process.

The ThermoCharger System meets a number of market needs:

- Heat recovery when space is scarce

- When available heat sinks are limited

- When investment dollars are small

- When squeezing every bit of efficiency out of a system is needed

Learn more about ThermoChargers

Learn more about ThermoChargers and how their relatively small price can provide a great return to your plant. Contact the team at Campbell-Sevey or click to download The Charge: Achieve Maximum Efficiency white paper.