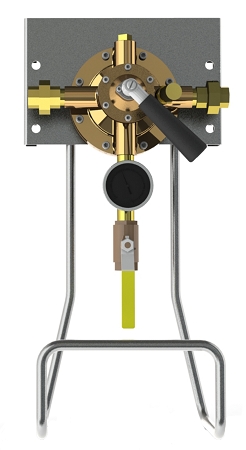

STEAMIX® Model 2032 is a steam/water mixing valve of brass/stainless steel construction. The valve is supplied as standard with 3/4″ inlet union connections, an outlet ball valve for flow control and an outlet dial thermometer. The unit is supplied fully assembled, pressure-tested and installed on a stainless steel hose rack.

STEAMIX® Steam and Water Hose Stations and Mixing Units will not pass live steam.

Steamix mixing valve, featured on all Steamix steam and water hose stations by Armstrong, will not pass live steam in the event of either a significant pressure reduction or complete failure of the cold-water supply.

Steamix is designed to improve efficiency and reduce risk when mixing steam and water for washdown. When your process demands high washdown temperatures, adjusting the mix of steam and water becomes much more difficult and dangerous. With the older style dual-globe valve mixing “Y,” it is too easy to introduce too much steam—with risky consequences for your personnel. Here’s why it’s no problem with Steamix.

STEAMIX® Model 2032 is a steam/water mixing valve of

brass/stainless steel construction. The valve is supplied as standard

with 3/4″ inlet union connections, an outlet ball valve for flow control

and an outlet dial thermometer. The unit is supplied fully assembled,

pressure-tested and installed on a stainless steel hose rack.

STEAMIX® Steam and Water Hose Stations and Mixing Units will not pass live steam.

Steamix mixing valve, featured on all Steamix steam and water hose stations by Armstrong, will not pass live steam in the event of either a significant pressure reduction or complete failure of the cold-water supply.

Steamix is designed to improve efficiency and reduce risk when mixing

steam and water for washdown. When your process demands high washdown

temperatures, adjusting the mix of steam and water becomes much more

difficult and dangerous. With the older style dual-globe valve mixing

“Y,” it is too easy to introduce too much steam—with risky consequences

for your personnel. Here’s why it’s no problem with Steamix.

For help in specifying the exact model you need, download the product literature.

No PDF available for download.

No PDF available for download.

No PDF available for download.

No PDF available for download.

No PDF available for download.

Copyright © 2025 Campbell-Sevey, Inc.