For air-heating coils, steam is the preferred medium for heat transfer throughout much of industry. Steam is easy and inexpensive to move from the boiler to the point of use, and it gives up much of its energy at a constant temperature when it condenses. Process control is easy and fast with steam, and there is essentially no lag time.

Making decisions about coil construction and materials is a multi-step process involving many factors. Armstrong’s line of heavy-duty steam coils is designed and manufactured to provide what you want most—long life and efficient heat transfer.

For air-heating

coils, steam is the preferred medium for heat transfer throughout much

of industry. Steam is easy and inexpensive to move from the boiler to

the point of use, and it gives up much of its energy at a constant

temperature when it condenses. Process control is easy and fast with

steam, and there is essentially no lag time.

Making decisions about coil construction and materials is a

multi-step process involving many factors. Armstrong’s line of

heavy-duty steam coils is designed and manufactured to provide what you

want most—long life and efficient heat transfer.

Standard coils (Type S)

This type of coil is used

for most applications where entering air temperatures are above 35°F

(2°C) and steam is at constant pressure. It is used extensively in

high-temperature process applications and for “reheat” in HVAC systems.

It is not, however, recommended where even outlet air temperatures are

required immediately after the coil, such as in multi-zone heating

systems or where a modulating steam control valve is used to control

temperature. (See drawing.)

Centifeed coils (Type C)

The single-row centifeed

coil can be used where air is below freezing and/or modulating control

is used. It is recommended where:

Two-row centifeed coils are available where (B) and (C) are required,

but tandem-type coils are a better choice with freezing air

temperatures.

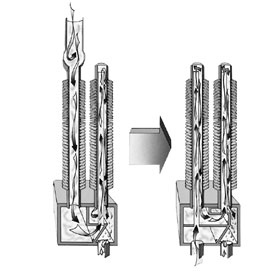

A centifeed coil is one plain tube—called the inner steam

distribution tube—inserted in an outer finned tube. The center tube is

fed with steam, which travels up this and is then discharged into the

outer tube. It then travels back between the outside wall of the

distribution tube and the inside wall of the finned tube to the

condensate header. The inner tube acts as a steam tracer to keep the

finned tube warm along its total length. (See drawing.)

Tandem coils (Types T and P)

Freezing

applications requiring more than one row to achieve the desired final

air temperature demand this type of a coil. The coil is designed so that

the total amount of steam to be condensed by the whole coil is fed into

the first row in the direction of airflow. This purges non-condensable

gases and droplets of condensate from that part of the coil exposed to

the coldest air. Channeling the steam from the header to the other rows

in the series has the same purging effect. This design ensures that air

passing over the last row is at least 35°F (2°C).

The coldest part of the coil will always have steam in sufficient

quantity to overcome unequal distribution and “backfeeding” due to

differing steam loads and pressure drops in adjacent tubes. This

eliminates freezing problems caused by condensate holdup.

The “series” feed characteristic of the tandem coil, as opposed to

the “parallel” feed of the two-row centifeed coil, makes it the ideal

choice for multi-row coils in freezing applications. If you want a

stainless steel tube tandem, specify a P type. (See drawings.)

For help in specifying the exact model you need, download the product literature.

No PDF available for download.

No PDF available for download.

No PDF available for download.

No PDF available for download.

Copyright © 2025 Campbell-Sevey, Inc.