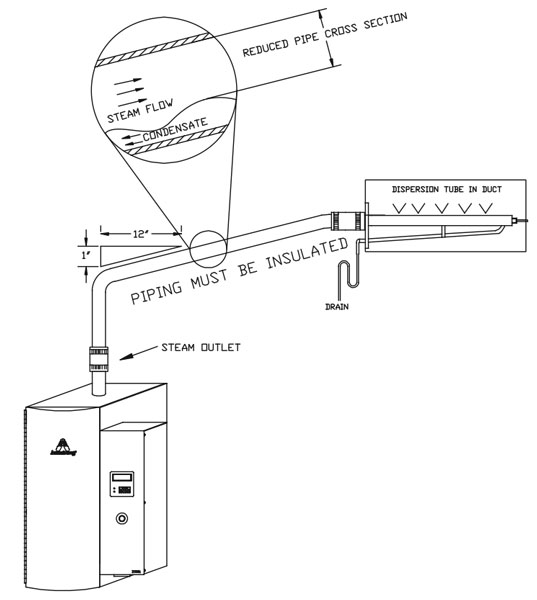

For all Armstrong Humidifiers, such as the Armstrong HC-6000 series, EHU-800, CS-10 or GFH, the slope of the dispersion piping should be 1″ per 12″. The illustration shows the importance of dispersion pipe slope. If the condensate is not removed efficiently, condensate could build up creating a reduced cross section of pipe for the opposing steam to flow which can cause back pressure at the humidifier.

Even on a system with correct slope there can still be a build up of condensate for dispersion runs that are longer than 20 equivalent feet. In these instances, it is recommend a drain be added in the middle of the dispersion run to eliminate excessive condensate.

Symptoms of back pressure are often level control related. Too much pressure on the outlet of the humidifier causes a pressure difference between the level control measurement canister and the main steam generation tank. Sometimes this can be fixed by the addition of a fill cup extension kit, but often times, the dispersion piping issues need to be corrected. On some humidifiers there may be an issue with back pressure forcing water down the overflow into the drain.

If you have questions about proper installation of Armstrong Humidifiers or other steam equipment, contact Campbell-Sevey. (Information from Armstrong International)

For all Armstrong Humidifiers, such as the Armstrong HC-6000 series, EHU-800, CS-10 or GFH, the slope of the dispersion piping should be 1″ per 12″. The illustration shows the importance of dispersion pipe slope. If the condensate is not removed efficiently, condensate could build up creating a reduced cross section of pipe for the opposing steam to flow which can cause back pressure at the humidifier.

Even on a system with correct slope there can still be a build up of condensate for dispersion runs that are longer than 20 equivalent feet. In these instances, it is recommend a drain be added in the middle of the dispersion run to eliminate excessive condensate.

Symptoms of back pressure are often level control related. Too much pressure on the outlet of the humidifier causes a pressure difference between the level control measurement canister and the main steam generation tank. Sometimes this can be fixed by the addition of a fill cup extension kit, but often times, the dispersion piping issues need to be corrected. On some humidifiers there may be an issue with back pressure forcing water down the overflow into the drain.

If you have questions about proper installation of Armstrong Humidifiers or other steam equipment, contact Campbell-Sevey. (Information from Armstrong International)How Important is Correct Slope and Condensate Drainage on Atmospheric Steam Dispersion Piping