While there is no such thing as a true “non‐freeze” steam coil (under the right circumstances any steam coil can freeze) there are coils that make it much more difficult to freeze. The proper description of these is “Steam Distributing” due to the tube-in-a-tube and header-in header construction method.

These coils all have an inner tube down the entire length of an outer tube. Even with these steam distribution coils, there are 2 different schools of thought: perforated and solid inner tubes.

Originally these coils were designed to evenly distribute the steam and condensate throughout the coil so there were no “dead spots” or “cold spots” in the coil. However after much testing, it was found that this type of coil was much more difficult to freeze than the standard conventional steam coil. Hence, the name “non‐freeze” surfaced.

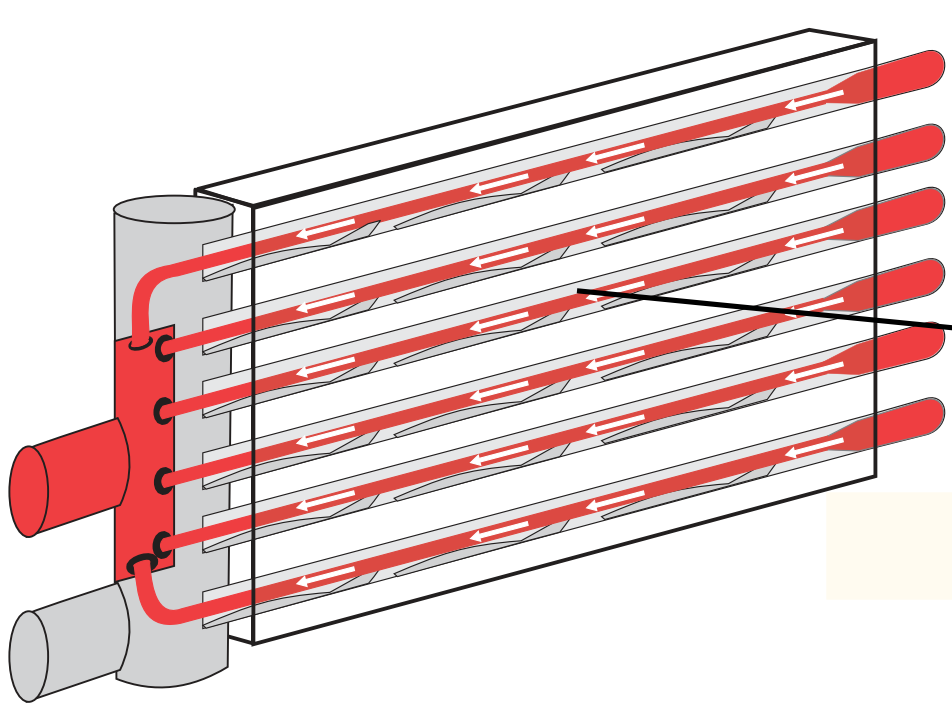

For lighter duty and HVAC applications, perforated inner tubes are usually used. This is the technology used in Heatcraft steam distribution coils. Steam is distributed from the inner supply header down the inner tubes evenly and is released to the outer condensing tubes through holes spaced about 9″ to 12″ apart. The outer tubes are “capped” with no return bends, so that the condensate generated in the outer condensing tubes and any non-condensable gasses have no place to go but back down the outer tube toward the outer condensate header and out the condensate connection.

While there is no such thing as a true “non‐freeze” steam coil (under the right circumstances any steam coil can freeze) there are coils that make it much more difficult to freeze. The proper description of these is “Steam Distributing” due to the tube-in-a-tube and header-in header construction method.

These coils all have an inner tube down the entire length of an outer tube. Even with these steam distribution coils, there are 2 different schools of thought: perforated and solid inner tubes.

Originally these coils were designed to evenly distribute the steam and condensate throughout the coil so there were no “dead spots” or “cold spots” in the coil. However after much testing, it was found that this type of coil was much more difficult to freeze than the standard conventional steam coil. Hence, the name “non‐freeze” surfaced.

For lighter duty and HVAC applications, perforated inner tubes are usually used. This is the technology used in Heatcraft steam distribution coils. Steam is distributed from the inner supply header down the inner tubes evenly and is released to the outer condensing tubes through holes spaced about 9″ to 12″ apart. The outer tubes are “capped” with no return bends, so that the condensate generated in the outer condensing tubes and any non-condensable gasses have no place to go but back down the outer tube toward the outer condensate header and out the condensate connection.

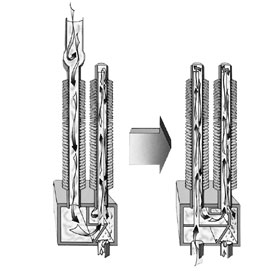

Armstrong’s centifeed coils are a good example of solid inner tube construction. They are also used where air is below freezing for freeze prevention. The difference is the steam path: all the steam travels all the way to the ends of the solid inner tubes. Then the steam moves to the outer condensing tubes and the condensate and non-condensable gasses are circuited to the condensate header. Because all the steam travels to the end of the inner tubes and back down the outer tubes, there can be no short-circuiting, which can trap gasses at the ends of the tubes and create cold spots and corrosion. The inner tubes need to be larger for all the steam to travel the length of the finned area, which makes the construction more expensive, but for some applications, it’s well worth it.

Today it’s standard practice to install these coils in applications where entering air temperatures are 40°F or below. Keep in mind however, that while non‐freeze coils don’t freeze easily, it’s possible to freeze them under the right conditions, and it happens when proper piping practices aren’t followed. Whether comfort or process air heating, contact Campbell-Sevey for your steam coil needs or to learn about proper piping practices to keep your coils from freezing.

Armstrong’s centifeed coils are a good example of solid inner tube construction. They are also used where air is below freezing for freeze prevention. The difference is the steam path: all the steam travels all the way to the ends of the solid inner tubes. Then the steam moves to the outer condensing tubes and the condensate and non-condensable gasses are circuited to the condensate header. Because all the steam travels to the end of the inner tubes and back down the outer tubes, there can be no short-circuiting, which can trap gasses at the ends of the tubes and create cold spots and corrosion. The inner tubes need to be larger for all the steam to travel the length of the finned area, which makes the construction more expensive, but for some applications, it’s well worth it.

Today it’s standard practice to install these coils in applications where entering air temperatures are 40°F or below. Keep in mind however, that while non‐freeze coils don’t freeze easily, it’s possible to freeze them under the right conditions, and it happens when proper piping practices aren’t followed. Whether comfort or process air heating, contact Campbell-Sevey for your steam coil needs or to learn about proper piping practices to keep your coils from freezing.

How Do Non-Freeze Steam Coils Operate?