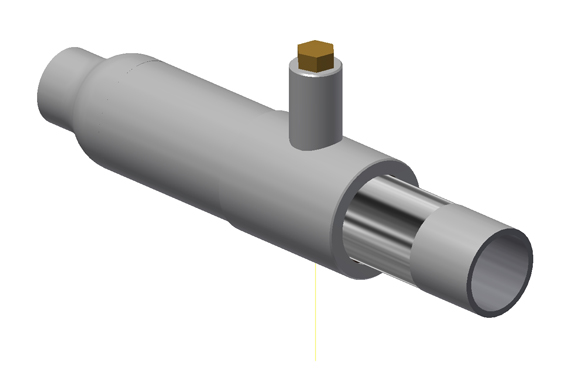

Everybody loves a bargain, however some bargains come at a high price. Expansion joints are designed with internal and external guides, which are integral with the joint’s stuffing box. The guides require close tolerance for effective guiding of the sliding slip and are critical to leak-free operation, but to be effective these guides must be concentric with each other. This requires costly manufacturing expense.

However, for sizes 12” and larger they found that the guide surfaces would distort from the heat of welding. Therefore, for joints of that size, machining the guide surfaces concentric needs to be done after the stuffing box to traverse chamber weld. This requires additional labor hours adding to costs.

Consulting engineers agree that the expansion joints’ internal and external guides must be concentric and they agree that the heat of welding may destroy any previously machined concentricity. That’s why when you need the most reliable joint possible, beware of low priced expansion joints. They may cost much more in the end.

Contact Campbell-Sevey to learn more about how we can assist you with your expansion joint needs.