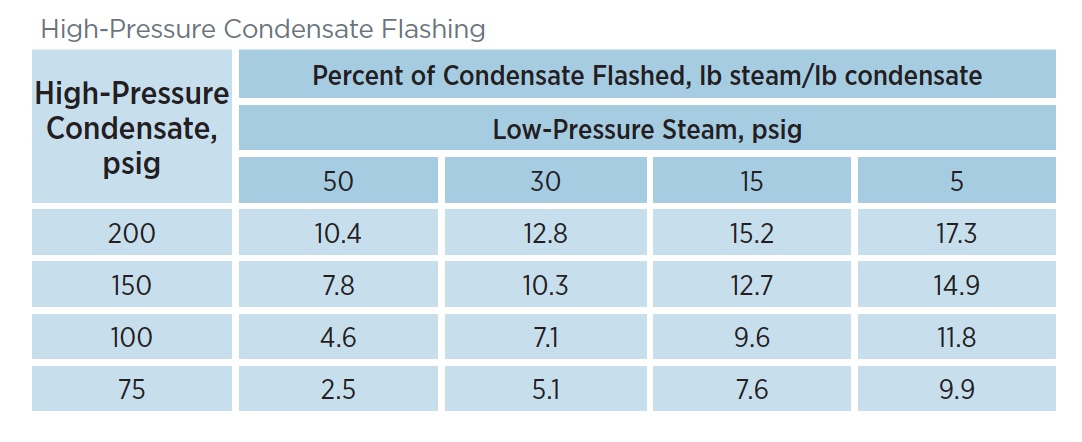

Low-pressure process steam requirements are usually met by throttling high-pressure steam, but a portion of the process requirements can be achieved at low cost by flashing high-pressure condensate. Flashing is particularly attractive when it is not economically feasible to return the high-pressure condensate to the boiler. In the table below, the quantity of steam obtained per pound of condensate flashed is given as a function of both condensate and steam pressures.

Example

In a plant where the cost of steam is $8.00 per million Btu ($8.00/MMBtu), saturated steam at 150 pounds per-square-inch-gauge (psig) is generated, and a portion of it throttled to supply 30-psig steam. Assuming continuous operation, determine the annual energy savings of producing low-pressure steam by flashing 5,000 pounds per hour (lb/hr) of 150-psig condensate. The average temperature of the boiler makeup water is 70°F.

From the table above, when 150-psig condensate is flashed at 30 psig, 10.3% of the condensate vaporizes.

- Low-Pressure Steam Produced = 5,000 lb/hr x 0.103 or 515 lb/hr

From the ASME Steam Tables, the enthalpy values are:

- For 30-psig saturated steam = 1,171.9 Btu/lb

- For 70ºF makeup water = 38.0 Btu/lb

Annual Savings are obtained as follows:

- 515 lb/hr x (1,171.9–38.0) Btu/lb

- x 8,760 hr/yr

- x $8.00/MMBtu]/106 Btu/MMBtu

- = $40,924

Proximity Is a Plus

The source of high-pressure condensate should be relatively close to the low-pressure steam usage to minimize piping and insulation costs.

Match Availability and Use

The economics of heat recovery projects are most favorable when the waste steam heat content is high and the flow is continuous. Seasonal space heating is not the most desirable end use.

This tip is provided by the U.S. Department of Energy – Energy Efficiency and Renewable Energy and originally published by the Industrial Energy Extension Service of Georgia Tech. For resources and suggested actions download the complete Steam Tip sheet from the U.S. Department of Energy.