Developed from direct contact water heating science, which was first introduced more than two decades ago, Complete Thermal Exchange (CTE) technology has revolutionized high efficiency water heating methods, rapidly become the new standard in water heating and energy savings.

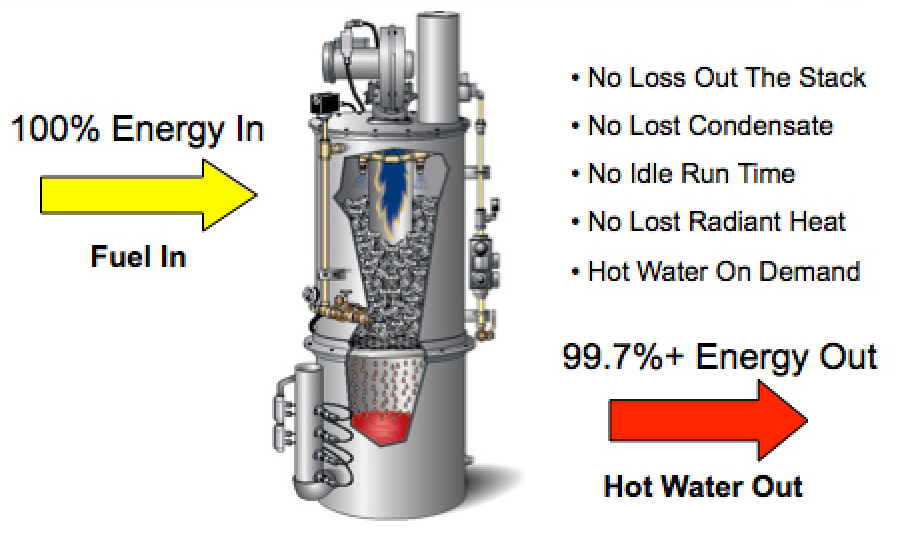

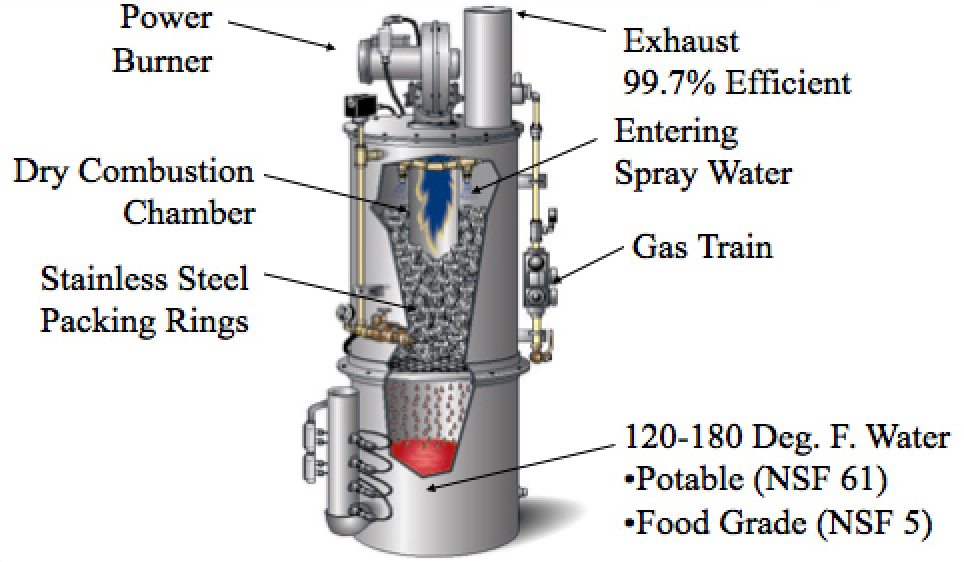

Developed from direct contact water heating science, which was first introduced more than two decades ago, Complete Thermal Exchange (CTE) technology has revolutionized high efficiency water heating methods, rapidly become the new standard in water heating and energy savings.While traditional direct contact water heating can offer significant energy savings when compared to a conventional steam boiler system, the Armstrong Flo-Direct® CTE gas fired water heater offers an unparalled 99.7% high heat value (110% approx. low heat value) efficiency rating throughout each phase of its operation cycle.

The sustained operational efficiency of Flo-Direct® CTE gas fired water heaters creates the most energy efficient method of hot water production currently available.

Cost Savings of a 7,000,000 B.T.U. CTE Water Heater over Boilers with Heat Exchangers

- Natural Gas cost per 1,000 cubic feet $9.00 p/1,000 cu.ft

- Hours per day continuous usage 10 hours

- Days of operation per year 350 days

- Gallons per minute average usage 112 gallons/min.

- Temperature of heated water 180 F. output

- Temperature of incoming water 55 F. input

- Temperature change (degrees delta) 125 F. change

- Boiler efficiency 82%

- System efficiency 90%

- Resulting Boiler/System efficiency 74% (when new)

- CTE Heater Efficiency 99.7%

The Flo-Direct® CTE direct contact water heaters, meet five standards not available with the older or more traditional methods of direct contact water heater technology:

- Same Efficiency Thoughout Operation – CTE units maintain a minimum of 99.7% high heat value (110% approx. low heat value) efficiency in all modes of operation, not just under optimal conditions.

- CTE Units Have Multiple Thermal Passes – Water and the combustion gasses (or heat from the combustion) repeatedly come in contact. This ensures that the maximum amount of heat or energy from combustion is transferred to the water.

- Lower Maintenance (No Scale Build Up) – The Flo-Direct® CTE gas fired water heater’s unique design prevents scale build-up because there are no “hot spots” internally or externally, and because calcium is prevented from completely falling out of suspension during operation. As a result, the mineral content of the influent water and the effluent water will be equal.

- Less CO2 Emissions – Many traditional-method direct contact water heaters spray water directly on the flame – called “flame quenching”. Flame quenching promotes incomplete combustion, and produces alcohols, aldehyde, formic acid, higher order acids, carbon monoxide, as well as carbon dioxide and water vapor. Flo-Direct®, using CTE technology, avoids this process altogether.

- Maintains Higher Water Quality – CTE units have an integral water quality integrity system to ensure that effluent water quality is equal to the influent water quality.

With unparalled 99.7% high heat value efficiency rating throughout each phase of its operation cycle, it’s no wonder CTE gas fired water heaters have become the new standard. To see the impact a CTE water heater could have on your system, contact the team at Campbell-Sevey.