During the process there are potential boiler system energy loss points. Of the nine primary ones listed below, which has the highest potential loss?

During the process there are potential boiler system energy loss points. Of the nine primary ones listed below, which has the highest potential loss?

- Air/Fuel Ratio Losses

- Scale Losses

- Boiler Stack Losses

- Boiler Radiant Losses

- Boiler Blowdown Losses

- Heat Exchange Losses

- Steam Leaks

- Lost Condensate

- Trap Losses

- Boiler Stack Losses (15%) – Some steam system losses are controllable and therefore may be reduced or eliminated, while others are inherent and can never be prevented. Boiler Stack Losses are a great example. Even the best tuned boiler with an economizer will have 85% or so efficiency or lower.

- Air/Fuel Ratio Losses – 4%

- Scale Losses – 10%

- Boiler Radiant Losses – 1%

- Boiler Blowdown Losses – 2.5%

- Heat Exchange Losses – 5%

- Steam Leaks – 3%

- Lost Condensate – 5%

- Trap Losses – 10%

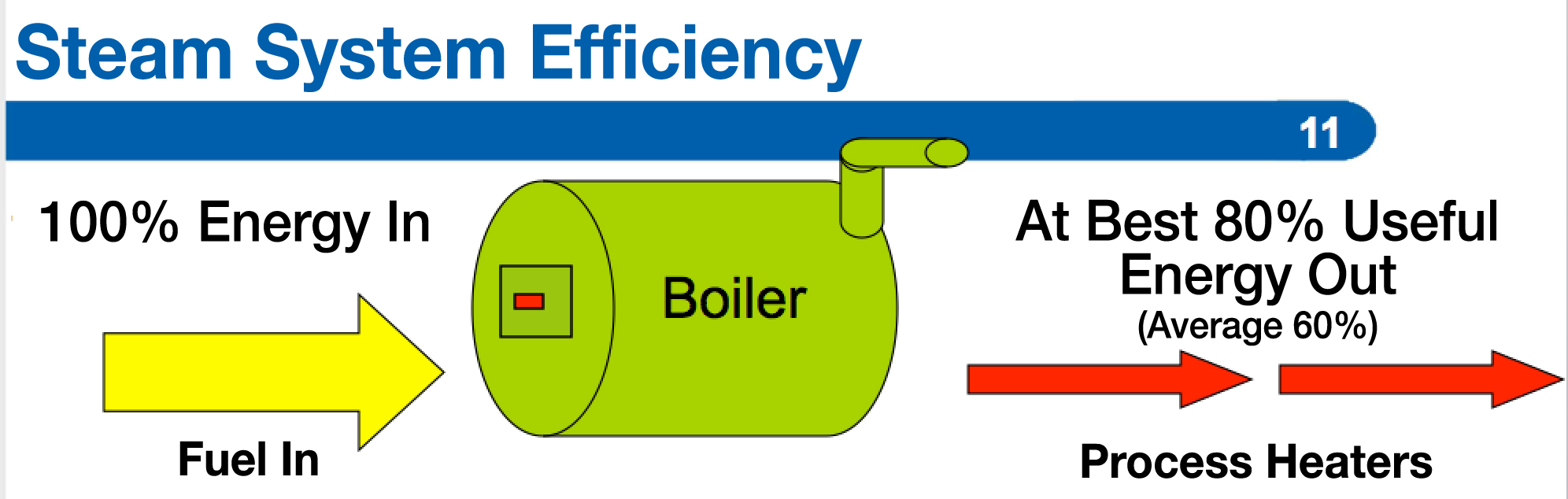

Test Your Knowledge: Steam System Efficiency