The key to a successful waste heat recovery project is optimizing the use of the recovered energy. By installing a condensing economizer, companies can improve overall heat recovery and steam system efficiency by up to 10%. Many boiler applications can benefit from this additional heat recovery, such as:

- district heating systems

- wallboard production facilities

- greenhouses

- food processing plants

- pulp and paper mills

- textile plants

- hospitals

Condensing economizers require site-specific engineering and design, and a thorough understanding of the effect they will have on the existing steam system and water chemistry.

Use this tip sheet and its companion, Considerations When Selecting a Condensing Economizer, to learn about these efficiency improvements or contact the team at Campbell-Sevey for help.

A conventional feedwater economizer reduces steam boiler fuel requirements by transferring heat from the flue gas to the boiler feedwater. For natural gas-fired boilers, the lowest temperature to which flue gas can be cooled is about 250°F to prevent condensation and possible stack or stack liner corrosion.

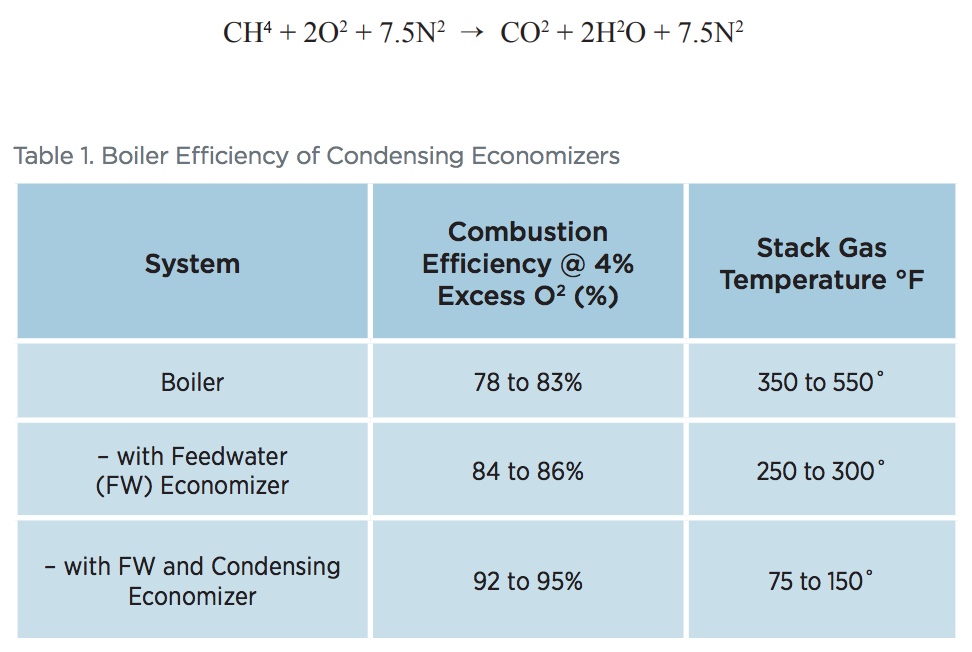

The condensing economizer improves waste heat recovery by cooling the flue gas below its dew point, which is about 135°F for products of combustion of natural gas. The economizer reclaims both sensible heat from the flue gas and latent heat by condensing flue gas water vapor (see Table 1). All hydrocarbon fuels release significant quantities of water vapor as a combustion byproduct. The equation below shows the reactants and combustion products for the stoichiometric combustion in air of methane (CH4), the primary constituent of natural gas. When one molecule of methane is burned, it produces two molecules of water vapor. When moles are converted to pound/mole, we find that every pound of methane fuel combusted produces 2.25 lb. of water vapor, which is about 12%of the total exhaust by weight.

Since the higher heating value of methane is 23,861 Btu per pound (Btu/lb), 41.9 lb of methane is required to provide one million Btu (MMBtu) of energy, resulting in 94.3 lb of high temperature water vapor. The latent heat of vaporization of water under atmospheric pressure is 970.3 Btu/lb. When one MMBtu of methane is combusted, 91,495 Btu of water vapor heat of evaporation (94.3 lb x 970.3 Btu/lb )is released up the boiler stack. This latent heat represents approximately 9% of the initial fuel energy content. The bulk of this latent heat can be recovered by cooling the exhaust gas below its dew point using a direct contact or indirect condensing economizer. It is possible to heat water to about 200°F with an indirect economizer or 140°F with a direct contact economizer.

Energy Savings Potential

The available heat in a boiler’s exhaust gases is dependent upon the hydrogen content of the fuel, the fuel firing rate, the percent of excess oxygen in the flue gases, and the stack gas temperature.

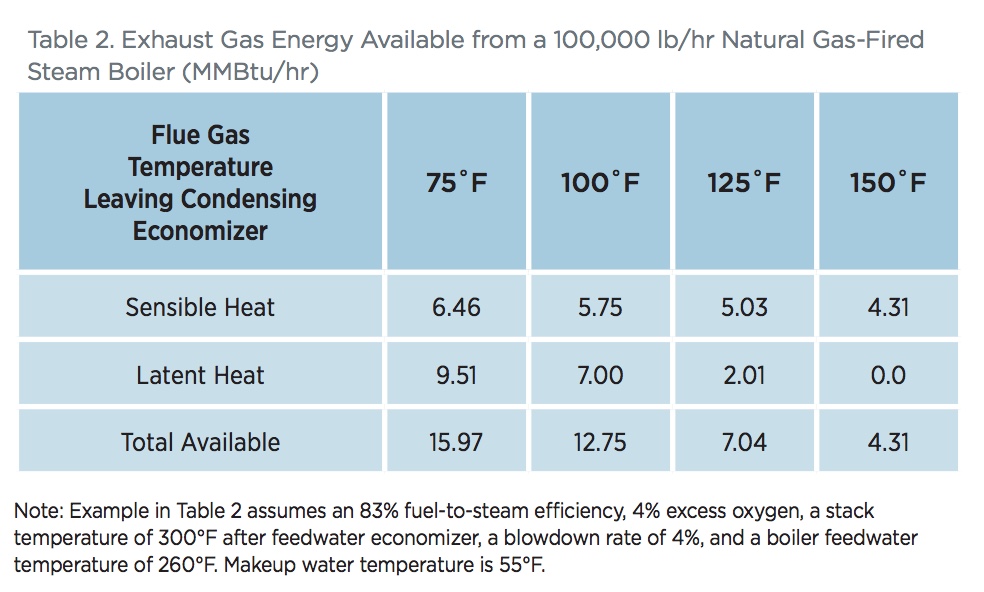

Consider a natural gas-fired boiler that produces 100,000 lb/hr of 100-psig saturated steam. At 83% efficiency, the boiler firing rate is about 116 MMBtu/hr. At its full firing rate, the boiler consumes over 4,860 lb of natural gas each hour while exhausting 10,938 lb of high temperature water vapor each hour. The water vapor in the flue gas contains over 10.6 MMBtu/hr of latent heat. As shown in Table 2, the total heat actually available for recovery is strongly dependent upon the stack gas temperature at the condensing economizer outlet.

Assume that an indirect contact condensing economizer is retrofitted onto this 100,000 lb/hr steam boiler to heat 50% of the makeup water from 55°F to 200°F and flue gases are cooled to 100°F. At these conditions, 12.75MMBtu/hr of total energy is available in the exhaust, of which 7.55 MMBtu/hr will be recovered to heat makeup water in the condensing economizer. More energy could be recovered if additional heat sinks are available.

Given 8,000 hours per year of boiler operation, and a fuel cost of $8.00/MMBtu, the annual energy recovered is valued at:

Annual Savings = 7.55MMBtu/hr x 8,000 hrs/yr x $8.00/MMBtu/0.83 = $582,170

Since the higher heating value of methane is 23,861 Btu per pound (Btu/lb), 41.9 lb of methane is required to provide one million Btu (MMBtu) of energy, resulting in 94.3 lb of high temperature water vapor. The latent heat of vaporization of water under atmospheric pressure is 970.3 Btu/lb. When one MMBtu of methane is combusted, 91,495 Btu of water vapor heat of evaporation (94.3 lb x 970.3 Btu/lb )is released up the boiler stack. This latent heat represents approximately 9% of the initial fuel energy content. The bulk of this latent heat can be recovered by cooling the exhaust gas below its dew point using a direct contact or indirect condensing economizer. It is possible to heat water to about 200°F with an indirect economizer or 140°F with a direct contact economizer.

Energy Savings Potential

The available heat in a boiler’s exhaust gases is dependent upon the hydrogen content of the fuel, the fuel firing rate, the percent of excess oxygen in the flue gases, and the stack gas temperature.

Consider a natural gas-fired boiler that produces 100,000 lb/hr of 100-psig saturated steam. At 83% efficiency, the boiler firing rate is about 116 MMBtu/hr. At its full firing rate, the boiler consumes over 4,860 lb of natural gas each hour while exhausting 10,938 lb of high temperature water vapor each hour. The water vapor in the flue gas contains over 10.6 MMBtu/hr of latent heat. As shown in Table 2, the total heat actually available for recovery is strongly dependent upon the stack gas temperature at the condensing economizer outlet.

Assume that an indirect contact condensing economizer is retrofitted onto this 100,000 lb/hr steam boiler to heat 50% of the makeup water from 55°F to 200°F and flue gases are cooled to 100°F. At these conditions, 12.75MMBtu/hr of total energy is available in the exhaust, of which 7.55 MMBtu/hr will be recovered to heat makeup water in the condensing economizer. More energy could be recovered if additional heat sinks are available.

Given 8,000 hours per year of boiler operation, and a fuel cost of $8.00/MMBtu, the annual energy recovered is valued at:

Annual Savings = 7.55MMBtu/hr x 8,000 hrs/yr x $8.00/MMBtu/0.83 = $582,170

For additional information on economizers, refer to Steam Tip Sheet #3 Use Feedwater Economizers for Waste Heat Recovery. This tip is provided by the U.S. Department of Energy – Energy Efficiency and Renewable Energy. For suggested actions and resources, click to download the complete US Department of Energy Tip Sheet.