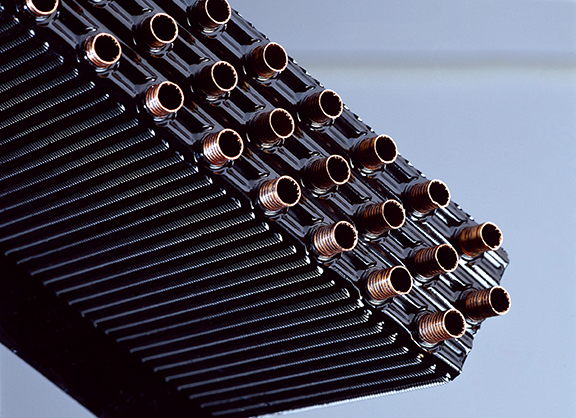

ElectroFin® E-Coat offers the highest level of corrosion protection available from an electro coating applicator. Recognized internationally, ElectroFin® E-Coat extends the lives of HVAC&R heat transfer coils and components while reducing maintenance and operating costs.

The ElectroFin® E-Coat process is strictly dedicated to coating heat transfer coils manufactured primarily from aluminum and copper for the HVAC&R and electrical power systems industries.

Our process utilizes deep cleaning of the coil, followed by a proprietary e-coating process involving PPG POWERCRON® and curing process that is only available from ElectroFin®. This is why ElectroFin® E-Coat is regarded internationally as the premier coating solution for all major HVAC&R OEMs.

The ElectroFin® E-Coat process guarantees complete and uniform encapsulation and 100% coverage. You can be assured that the coating penetrates into all coil cavities, covers the entire coil assembly, and provides superior protection in the most severe environments.

ElectroFin® E-Coat offers the highest level of corrosion protection available from an electro coating applicator. Recognized internationally, ElectroFin® E-Coat extends the lives of HVAC&R heat transfer coils and components while reducing maintenance and operating costs.

The ElectroFin® E-Coat process is strictly dedicated to coating heat transfer coils manufactured primarily from aluminum and copper for the HVAC&R and electrical power systems industries.

Our process utilizes deep cleaning of the coil, followed by a proprietary e-coating process involving PPG POWERCRON® and curing process that is only available from ElectroFin®. This is why ElectroFin® E-Coat is regarded internationally as the premier coating solution for all major HVAC&R OEMs.

The ElectroFin® E-Coat process guarantees complete and uniform encapsulation and 100% coverage. You can be assured that the coating penetrates into all coil cavities, covers the entire coil assembly, and provides superior protection in the most severe environments.

Product Information

Technical Data Sheets

Safety Data Sheets

No PDF available for download.

No PDF available for download.

No PDF available for download.

No PDF available for download.

No PDF available for download.

No PDF available for download.

No PDF available for download.

No PDF available for download.

No PDF available for download.

Copyright © 2025 Campbell-Sevey, Inc.