Product List

Find a product

Information

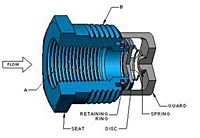

DFT – 8023 SS-BSSH7 Model Check Valve In-Line Threaded Check Valve

Description

The DFT® Basic-Check valve is a versatile all-purpose, spring-assisted, in-line check valve that provides reliable, low maintenance service for a wide range of liquids and gases at various pressure/temperature combinations. The valve consists of a guard cage, spring, valve disc, retaining ring and seat. It can be combined with pipe fittings such as reducing couplings, drain elbows, etc. to form a complete check valve unit ideally suited for a broad range of pipeline applications or incorporated into machinery for OEM applications. The metal-to-metal sealing area of the Basic-Check valve’s disc and seat is precision lapped, providing very tight shut-off of both gas and liquid. If bubble-tight shut-off is required, resilient soft seats are available.

Request a QuoteContact Form

Basic-Check®

DN 20

0.75 in

0.75 in

BSSH7

1.50 in

13.2

6

1.8

0.44 psi

0.030 bar

12.1 in.water

307 mm.water

22.6 mmHg

±10%

0.88 lb

0.4 kg

0 psig

6000 psig

0 barg

414 barg

1 Cracking pressure for vertical flow will be slightly different: upward flow, slightly higher; downward flow, slightly less.

Not recommended for use on discharge of reciprocating compressors.

2 Contingent on service ratings of matching pipe and fittings.

316 SS

17-7 SS

CF8M

316 SS

316 SS

Buna-N -49 (-70 to 250°F)

EPDM -57 (-75 to 300°F)

TFE®-Viton -98 (-40 to 400°F)

Viton® -51 (-40 to 400°F)

Zelon® -54 (37 to 400°F)

1 Soft seats are not available for the Style BSE check Valve. Buna-N and Viton are not suitable for steam service.

Inconel® X-750 (-460 to 700°F)

316 SS (-460 to 450°F)

NPT

6000 CWP

316 SS

B1.20.1

SP-25

- 1/4″ to 2 1/2″ Line size

- 450 to 6000 CWP

- Threaded ends

- Stainless Steel Construction

- Spring-assisted silent closing

- Horizontal or vertical installation

- Tight shut-off – lapped disc & seat

- Easy Maintenance

- Versatile

- Inconel® 750 Spring

- Soft seat