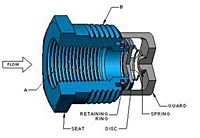

The DFT® Basic-Check valve is a versatile all-purpose, spring-assisted, in-line check valve that provides reliable, low maintenance service for a wide range of liquids and gases at various pressure/temperature combinations. The valve consists of a guard cage, spring, valve disc, retaining ring and seat. It can be combined with pipe fittings such as reducing couplings, drain elbows, etc. to form a complete check valve unit ideally suited for a broad range of pipeline applications or incorporated into machinery for OEM applications. The metal-to-metal sealing area of the Basic-Check valve’s disc and seat is precision lapped, providing very tight shut-off of both gas and liquid. If bubble-tight shut-off is required, resilient soft seats are available.

The DFT® Basic-Check valve is a versatile all-purpose, spring-assisted, in-line check valve that provides reliable, low maintenance service for a wide range of liquids and gases at various pressure/temperature combinations. The valve consists of a guard cage, spring, valve disc, retaining ring and seat. It can be combined with pipe fittings such as reducing couplings, drain elbows, etc. to form a complete check valve unit ideally suited for a broad range of pipeline applications or incorporated into machinery for OEM applications. The metal-to-metal sealing area of the Basic-Check valve’s disc and seat is precision lapped, providing very tight shut-off of both gas and liquid. If bubble-tight shut-off is required, resilient soft seats are available. |

|||||||||||||||||

|

|||||||||||||||||

No PDF available for download.

No PDF available for download.

No PDF available for download.

No PDF available for download.

No PDF available for download.

No PDF available for download.

No PDF available for download.

No PDF available for download.

No PDF available for download.

No PDF available for download.

No PDF available for download.

Copyright © 2025 Campbell-Sevey, Inc.