The Aar-O-Vent® high performance air and dirt separator is a product we highly recommend as a way to increase performance and protect against corrosion in hydronic systems.

Heating/cooling system efficiency and component life is greatly dependent on water quality. Air and dirt particles can cause pump cavitation, corrosion and increased component wear. In a closed loop system, the Aar-O-Vent eliminates air bubbles, entrained air and dirt particles quickly and easily.

Each Aar-O-Vent model uses a patented stainless steel coalescing filter medium that eliminates virtually any dirt particles, air bubbles and/or entrained air from the water by means of an air eliminator or blowdown valve.

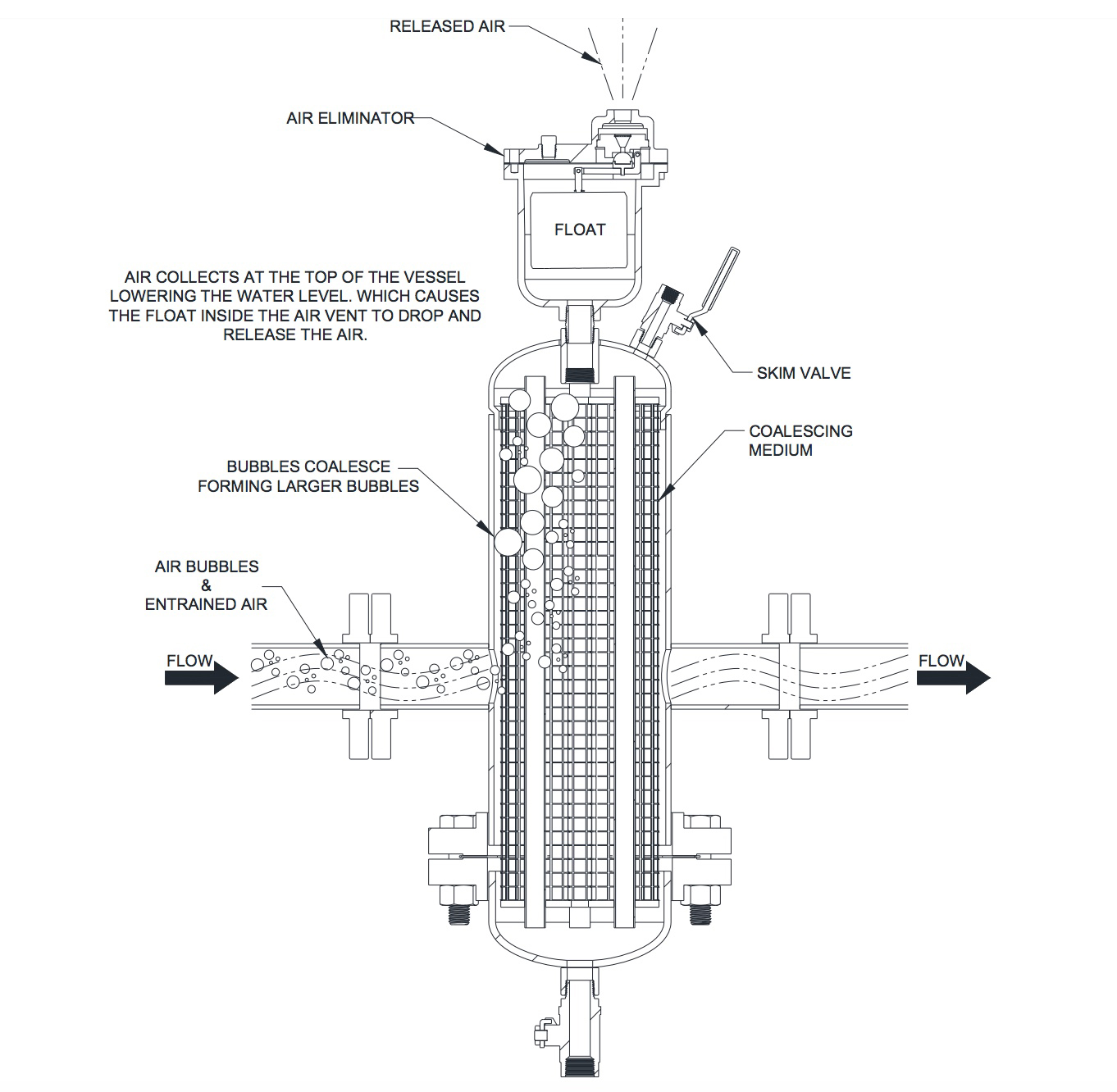

How Air Elimination Works in the Aar-O-Vent

- Large air bubbles in the system water enter the Aar-O-Vent and collide with the coalescing medium. They quickly rise to the top of the vessel and into the air elimination device.

- Micro bubbles coalesce and form larger bubbles. The larger bubbles then rise to the top of the vessel and into the air elimination device.

- Entrained air is pulled out of solution and forms micro bubbles. The micro bubbles coalesce forming larger bubbles. The larger bubbles rise to the top of the vessel and into the air elimination device.

- As air bubbles collect at the top of the vessel they create an air pocket. This pocket of air pushes the water level down inside the vessel. As the water level drops, the float inside of the air elimination device also drops releasing the air to atmosphere.

- The air elimination device releases air as fast as it can be separated. It will not allow air back into the system, even if a vacuum occurs.

- Once the air has been released, the water level will rise inside the vessel. This causes the float to rise and close the air elimination device.

- This cycle will continue as new water is introduced into the system piping. With each pass of system water the Aar-O-Vent will eventually eliminate up to 99.7% of dissolved oxygen content in the system piping.

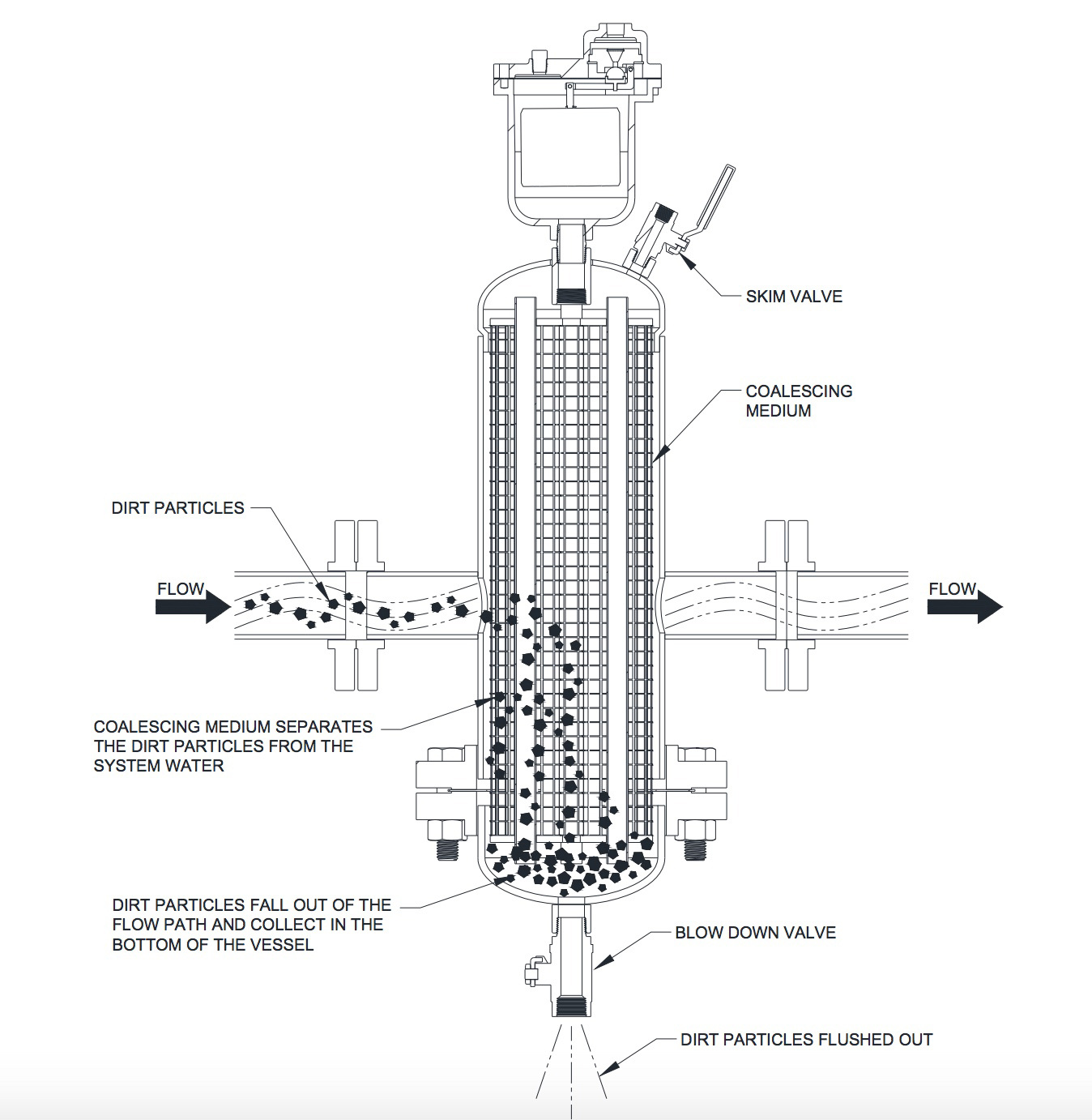

How Dirt is Eliminated in the Aar-O-Vent

- Dirt particles in the system water enter the Aar-O-Vent and collide with the coalescing medium.

- The coalescing medium creates an area of less turbulence allowing the dirt particles to fall out of the flow path and to the bottom of the vessel.

- Dirt particles will continue to collect at the bottom of the vessel until they are flushed out through the blow down valve.

- Floating debris can be flushed out by opening the skim valve located on the top of the vessel.

- Should the need to clean the coalescing medium arise, the removable head provides ease of removal and cleaning.

Click to learn more about the HVR and SVR Aar-O-Vent series or contact the team at Campbell-Sevey to see how the Aar-O-Vent could improve the performance of your system