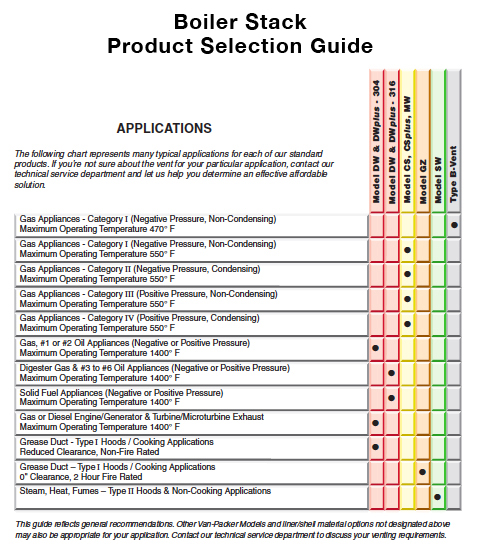

There are a lot of critical factors that apply when selecting the right boiler stack for your application. This guide from Van-Packer Co. provided detailed information on a variety of systems including:

Double-Wall Chimney and Breeching Systems: Double wall air or fiber insulated systems for venting boilers, kilns, cooking equipment (grease ducts), emergency generators, coffee roasters, etc.

Two-Hour Fire Rated Zero Clearance Grease Duct: Double wall ceramic fiber insulated duct for the removal of smoke and grease effluent from commercial, industrial, institutional, and similar cooking applications. Model GZ grease duct is an alternate to a specified hourly rated fire resistive shaft enclosure.

Special Gas Vent for Condensing Chimney and Breeching Systems: Double wall air or fiber insulated (Models CS & CSplus) and single wall (Model MW) corrosion resistant systems for venting gas appliances.

Single Wall Fume Hoods, Particle Containment, Breeching Systems: Single wall exhaust systems for venting caustic air, fume hoods, particle containment, breeching for boilers and heating appliances.

Gas Vent for Appliances Equipped with Draft Hoods/Diverters: Double wall air or fiber insulated corrosion resistant systems for venting gas appliances equipped with draft hoods or diverters and other Category I appliances listed for use with Type B gas vents.

Engineered Chimneys: Our engineers will provide specific designs including sizing, structural, corrosion, and thermal analysis to exhaust products of combustion as specified. Van-Packer’s engineers can design unique stacks; for example, a single freestanding stack containing multiple chimney systems.

Click here to download the complete guide or contact Campbell-Sevey for recommendations on what is best for your application.