Advanced Thermal Systems (ATS) has long been recognized as the leader in the manufacture of packed slip type expansion joints. Essentially all of the advances in the design of packed expansion joints over the past 40 years were developed by ATS.

The following is a comparison between their standard expansion joints and those of their two major competitors; Adsco and Hyspan. If no specific difference is listed; it is assumed that the supplier at least meets the minimum requirements of the specification.

- Advanced Thermal Systems is the only manufacturer whose expansion joints are designed in strict compliance with the ASTM F 1007 Specification covering packed slip type expansion joints. Both Adsco’s and Hyspan’s designs are based on the requirements of Military Specification MIL-E-17814F which was discontinued several years ago and replaced by the more stringent ATSM Specification.

- The slips on ATS expansion joints are polished to a 16 RMS finish and plated with 2 mils of hard chrome followed by a final polish to ensure a smooth sliding surface. This process exceeds the ANSI B 650 class 50 requirements of the ASTM F 1007 Specification. Adsco’s standard plating process is decorative chrome, which consists of a flash coating of chrome over nickel. This process does not meet the requirements of either the ASTM or Military Specifications. Adsco does offer hard chrome plating; but only if it is in the specification.

- The total available slip travel on ATS expansion joints is the rated travel plus one (1) extra inch of factory pre-compression. This extra pre-compression allows the slip to extend without loading the limit stops. This becomes important in the event that the system temperature ever falls below the installation temperature. Adsco’s expansion joints do not include any pre-compression.

- ATS expansion joints are factory packed through a series of half couplings, which are located around the outer circumference of the stuffing box. Injecting packing through these factory fill connections allows us to visually confirm uniform packing distribution. Both Adsco’s and Hyspan’s expansion joints are packed through the packing cylinders. The small internal diameter at the bottom of the packing cylinder necessitates that very high pressures be reached to force the packing into the stuffing box. Packing the expansion joints in this manner can result in high-density packing immediately below the packing cylinder, uneven packing distribution and the potential for slip collapse.

- The ASTM F 1007 Specification states, “the force to compress or extend the slip of the expansion joint shall not exceed 1000 lb/in of nominal pipe diameter”. For example, the force required to compress the slip on a 4” expansion joint would be 4,000 pounds. ATS standard TP2 expansion joints have always met this requirement.

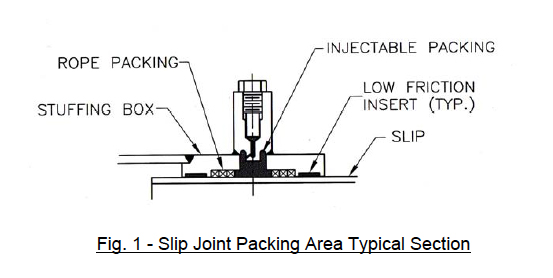

Figure 1 shows a section through the packing area of a typical ATS slip type expansion joint.

- Packed slip type expansion joints use rings of rope packing placed on either side of the injectable zone. These rings serve to contain the injectable packing and allow for adequate packing pressure (density) to be developed to ensure an effective seal. All ATS packed slip type expansion joints use a minimum of three (3) rings of rope packing on either side of the injectable zone. The packing surface area in contact with the sliding slip is designed to be equal to at least fifteen (15) times the expansion joints nominal pipe size. Hyspan Perma-Pax joints are designed with only two (2) rings on either side and a very narrow injectable zone.

- One of the most significant developments in the design of packed slip type expansion joints is the use of low friction non-metallic guide inserts. ATS expansion joints include internal and external guides manufactured from a bronze filled Teflon material. These inserts serve to protect the slip from damage in the event that misalignment occurs during service as well as to reduce the potential for binding within the joint. The ATSM F 1007 Specification calls for low friction guides to prevent scoring or binding of the slip. Both Adsco and Hyspan use bronze (or brass) inserts which may protect the slip to some degree, but they are not low friction materials and will do little to reduce the potential for scoring or binding if misalignment occurs.

ATS expansion joints may not be the least expensive; but their quality is the best that is available. In addition they are backed by their “5 Year Leak Free Warranty” as well as unsurpassed factory service in the event that a problem arises during system installation or operation. Keep in mind that Campbell-Sevey only sells products that are industry leaders in performance and reliability.

Contact Campbell-Sevey for your expansion joint needs.