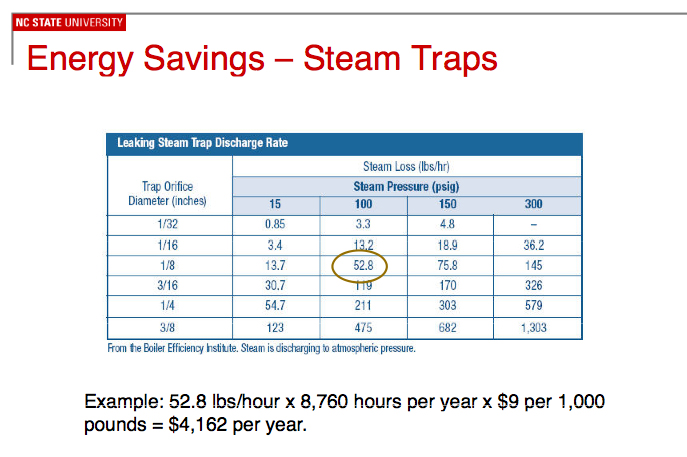

As you can see, a single steam trap with a hole even the size of a BB can cost thousands of dollars in steam loss. When multiplied over numerous traps and an industry-wide average of 5-20% leaking at any time, the losses can be very high, on the order of $60,000 annually for each 100 steam traps in a building/system. For instance, In 1998 DuPont saved $1 million a year at one New Jersey facility simply by testing and repairing defective steam traps.

As you can see, a single steam trap with a hole even the size of a BB can cost thousands of dollars in steam loss. When multiplied over numerous traps and an industry-wide average of 5-20% leaking at any time, the losses can be very high, on the order of $60,000 annually for each 100 steam traps in a building/system. For instance, In 1998 DuPont saved $1 million a year at one New Jersey facility simply by testing and repairing defective steam traps.

The Main Functions of Steam Traps

The three main functions of a steam trap are to remove condensate as soon as it forms, to prevent live steam loss and to remove air from the system. These are accomplished by venting gases, discharging condensate and trapping live steam. By doing this, steam traps prevent plants from wasting energy and losing efficiency. Plant managers should conduct annual steam trap surveys which can accomplish a variety of goals:1. Improve efficiency:

Built-up condensate or air and other non-condensible gasses can slow start up and reduce process efficiency on heat exchange devices.2. Reduce safety risk:

Backed up condensate from steam traps that fail closed can cause catastrophic failure of steam line equipment.3. Increase energy savings:

Every leak detected and fixed directly reduces steam loss and increases energy savings.4. Reduce the impact of trap failure:

By proactively testing steam traps, plant managers can detect trap failures quickly and minimize any loss.5. Detect larger issues:

If steam traps regularly fail in an area it may be caused by other equipment issues such as poor piping layout, or other failed components.6. Prevent downtime:

By proactively surveying traps, plant managers can avoid equipment failure and eliminate downtime.Steam Trap Surveys and Monitoring

Steam Trap Surveys are one way we have of capturing wasted energy. Campbell-Sevey’s trap technicians visit every steam trap in your facility and gather more than 25 data points on each one. These data are carefully logged into proprietary software that calculates annual energy losses. Armstrong’s SteamEye Steam Trap Monitoring System can also be installed on every steam trap and steam safety valve. This system resides on a plant’s computer network and will monitor the condition of every trap and safety valve continuously. When failures occur, it will notify system operators instantly, reducing the time from failure to repair from years to minutes. Campbell-Sevey works with local utilities to utilize all available rebates for you as well. And, of course, replacement traps and repair parts are locally stocked. For more information on Campbell-Sevey’s steam trap and safety valve surveys, or to see if SteamEye Monitoring is right for your system, contact the team at Campbell-Sevey.Are Your Steam Costs Rising? Time to Check Your Steam Traps