Campbell-Sevey Difference

“We have proven again and again that we understand the specific challenges facing our customers. For over 80 years, Campbell-Sevey has been dedicated to helping customers find improved productivity and reduced maintenance costs in their steam, air, and water systems. We have worked with every kind of system application and field-tested every component.”

– Steve Graves, President

We serve your industry.

Regardless of which industry in which you work, our sales and service engineers are ready to provide the on-going product, technical and service support at every level of system design and operation.

We have over 8 decades of technical and field experience in all phases of steam system, boiler system, and HVAC system product support, training, supervision, and auditing. We only sell quality energy system products that are from the industry leaders in performance and reliability.

Choose your industry and learn how we can help you for the specialized needs of your energy systems.

REFINERIES & BIOFUEL

Safety, quality and cost efficiency are huge priorities at refineries and ethanol plants, which is why at Campbell-Sevey we can help you to incorporate intelligent HVAC solutions into your working environment. With efficient heating solutions, you can ensure optimal efficiency and comfort.

HOSPITALITY

By working with Campbell-Sevey, Hospitality Engineers can analyze the energy system design and layout to highlight areas that are problematic and could be improved.

HEALTHCARE

By working with Campbell-Sevey, Hospital Operations Engineers can analyse the energy system design and layout to highlight areas that are problematic and could be improved.

HIGHER EDUCATION

Schools and Universities require sophisticated energy systems that cater to a range of different rooms and spaces, including classrooms, auditoriums and athletic facilities.

FOOD & BEVERAGE

The food and beverage industry is highly competitive, which means commercial businesses use Campbell-Sevey to maintain a high standard of health and solution efficiency.

POWER & MANUFACTURING

Campbell-Sevey provides expert power plant energy system parts and solutions. Working with power plant service providers, we boiler design and recommend parts and equipment.

INDUSTRIAL PROCESSING

Processing facilities require specialized energy systems, distribution, recovery and utilization to create optimal conditions in which processing facilities can best operate.

We Help Energy Systems Achieve Maximum Potential

The Campbell-Sevey team has extensive knowledge, specialized experience in industrial and commercial boiler system solutions and efficient heating solutions. By improving and maximizing energy system optimization, your long-term savings are increased. We have in depth understanding of HVAC solutions, meaning we are the authority on energy system design, products, and industry solutions.

Steam Energy Conservation Seminars

When you attend a Campbell-Sevey Steam Energy Conservation seminar, you will gain specialized knowledge on steam systems and steam boiler operation and maintenance, which you can translate into practical skills and an understanding of how smart steam boiler services can help you save energy, time and money. During the “live steam system” seminar at the Campbell-Sevey offices in Minnetonka, MN, you will learn about the behavior of various steam system elements. You will get a live insight into steam traps, pressure reduction and relief valve selection, operation and testing.

Upcoming Seminars

- March 19

- April 16

- May 21

- June 18

- July 16

- August 20

- September 17

- October 15

- November 19

- December 17

Who Should Attend?

- Plant Managers and Operators

- Operations Engineers

- Consulting Engineers

- Contractors

- Energy Managers

Rental Boilers & Equipment

Do you need to rent a boiler for added capacity, planned maintenance, or for an unplanned event? Campbell-Sevey can help.

PRODUCT LINES & MANUFACTURERS

We only sell products that are industry leaders in performance and reliability. Our Sales and Service Engineers are ready to provide the on-going product, technical and service support at every level of utility system design and operation, in regards to industrial boiler solutions, HVAC solutions and steam boiler service in Minneapolis and the entire Midwest.

Our Process. Your Success.

Educate

With Campbell-Sevey, our education and support starts with hello – and it doesn’t stop there. We support your advancement and your energy systems run at the highest level of performance possible.

Evaluate

We help you conduct an in-depth audit on your energy systems to uncover any and all deficiencies, problems, and failures.

Engineer

Next, we review the results to educate and recommend to improvements to energy usage, effectiveness, and efficiency.

Execute

We create detailed plans, a cost/benefit analysis and work with your team on system installation and maintenance.

Latest News

Let’s Talk About Humidifiers

The concept of humidification is relatively simple. It’s the act of adding water vapor into dry air. A key measurement of humidity is called relative humidity, or RH. This is the amount of vapor in the air compared to the amount the air can hold at a given temperature. Warm air can hold significantly more […]

Read More

Campbell-Sevey to attend the 2024 ABMA Boiler Technology Conference and Expo

Campbell-Sevey is thrilled to announce that we will be participating in the upcoming American Boiler Manufacturers Association (ABMA) Boiler Technology Conference and Expo, scheduled to take place in Denver, CO, from May 1-3, 2024. As a leading player in the boiler industry, we understand the importance of staying ahead in technology, networking with industry experts, […]

Read More

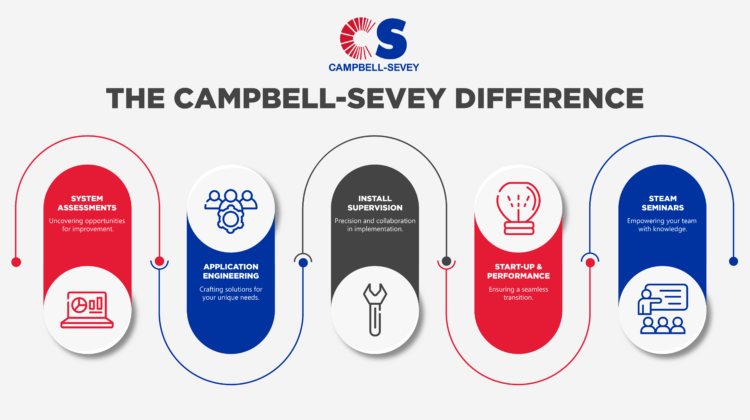

Unveiling the Campbell-Sevey Difference: Elevating Steam System Efficiency

In the intricate world of industrial processes, the efficiency of steam systems is paramount. At Campbell-Sevey, we go beyond providing mere solutions – we deliver a comprehensive suite of services designed to address the unique challenges faced by our customers. Join us as we explore how our key offerings – application engineering, start-up, and performance, […]

Read MoreGet Started

Work with the world’s most innovative boiler, HVAC, and steam systems solutions company. With over 250 combined years of sales/engineering experience in industrial boiler system solutions, HVAC system solutions and steam boiler system solutions, we offer support for engineering, product sizing and specification, product and system sales, installation and technical support, parts and boiler repair service. We are supported by an extensive local stock of quality energy system products.